FlareSens emissions monitoring

FlareSens provides continuous emissions monitoring for flare gas systems, combining flow data with gas compositions to power your emissions analysis and reporting

RELEASING THE POWER BEHIND THE DATA

Revolutionizing Emissions Monitoring: Introducing Fluenta's FlareSens System

FlareSens

In the ever-evolving landscape of the oil and gas industry, the demand for precise emissions monitoring and reporting has never been more critical. With increasing regulatory, financial, and environmental pressures, operators need advanced solutions to stay compliant and efficient. Fluenta’s latest innovation, the FlareSens system, promises to meet these demands by providing comprehensive emissions data and analysis, making it a game-changer for the sector.

The FlareSens system shines in its ability to deliver accurate emissions data and net heating value calculations, addressing the tightening regulations from global agencies such as the EPA and the European Union. Even beyond fiscal regulation, and as scrutiny on methane emissions intensifies, driven by open data sources like MethaneSat and CarbonMapper, operators are rightly self-policing through agreements such as GFMR and OGMP 2. FlareSens not only ensures compliance with these, but also empowers companies to achieve cost savings and enhance their public perception through improved analysis and combustion efficiency reporting.

Financial pressures are already escalating, with methane emissions now subject to taxation under frameworks like the Inflation Reduction Act in the USA. Starting at $900 per tonne in 2024 and rising to $1,500 per tonne by 2026, the need for precise monitoring is more pressing than ever. FlareSens offers a sophisticated solution that helps operators avoid costly inefficiencies by providing real-time and historical data crucial for compliance and diagnostics. This system ensures that companies are prepared for both current and future regulatory changes.

Increasing Regulation of Methane

Methane Measurement for OGMP 2.0

A recent study by MethaneSAT (read here) confirms what the industry has long suspected—smaller, dispersed methane sources account for the majority of emissions in the U.S. oil and gas sector. The study highlights a fundamental flaw in methane reduction strategies: while satellite data provides a big-picture view, it lacks the real-time accuracy needed to control […]

Methane – The Elephant in the Room

Gram for gram, Methane emissions are at least 28 times as damaging to the environment as CO2 and they are becomming the hottest issue in environmental regulation

The Impact of the Inflation Reduction Act on Reducing Methane Emissions in the U.S. Oil and Gas Industry

The Impact of the Inflation Reduction Act on Flaring in the U.S. Oil and Gas Industry The Inflation Reduction Act (IRA), signed into law in August 2022, includes various measures aimed at addressing climate change, with a focus on reducing methane emissions, particularly from flaring in the oil and gas sector. One of the act’s […]

A Quick Guide on New BLM Flaring and Venting Regulations for U.S. Oil and Gas Operators

The new BLM regulations on flare gas measurement and waste prevention mark a significant shift towards more sustainable and efficient oil and gas production practices.

The Impact of the European Methane Regulation on Flaring in the Oil and Gas Industry

EU Methane Regulation in the Oil and Gas Industry

Features and Highlights

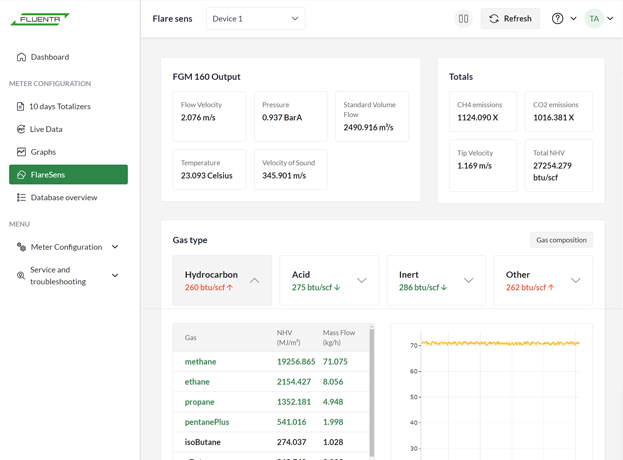

As Methane and CO2 emissions are dominating the agenda in energy debates, the regulation around this area is tightening significantly. FlareSens provides a granular perspective on your live emissions as well as continuously logging all your data for reporting purposes.

Combining the most accurate flare gas flow measurement in the industry with detailed gas compositions allows not only in-depth analysis of combustion, but a deep understanding of potential operational and opportunity losses.

FlareSens integrates to pull data from multiple sources, allowing better and more accurate ‘in-situ’ measurement rather than calculated emissions values. As data from satellites enters the public domain, the self-regulation that FlareSens enables is essential to stay ahead, not only of regulations, but more importantly, public opinion.

Key Specifications

Product Name

FlareSens

Primary Function

Continuous emissions monitoring and logging system

Key Components

19″ Rack mount unit to be housed in Safe Area,

Fluenta FGM 160 Ultrasonic Flare Measurement System (or other)

Laptop or other device required for setup and UI

Communication

Primary FlareSens comms – Modbus over RS485, Modbus over TCP/IP, Ethernet (RJ45)

Power Supply

- AC mains source (85 – 265 Vac)

Enclosure

19” rack enclosure, 2U height (concept render)

UI Access

Ethernet link to a PC (no wireless access for beta)

Key Calculations

Net Heating Value (NHV),

Flare Tip Velocity,

Emissions (CO2, CH4)

Supported Gases

Acetylene, Benzene, 1,2-Butadiene, 1,3-Butadiene, iso-Butane, n-Butane, cis-Butene, iso-Butene, trans-Butene, Carbon Dioxide, Carbon Monoxide, Cyclopropane, Ethane, Ethylene, Hydrogen, Hydrogen Sulphide, Methane, Methyl-Acetylene, Nitrogen, Oxygen, Pentane+, Propadiene, Propane, Propylene, Water

Inputs

Gas flow velocity, Volume flow, Temperature, Pressure, Gas composition, NHV per gas component, Volumetric flow of steam, assist air, and pilot gas, Flare exit diameter, Flare exit speed, Wind speed

Outputs

Gas flow velocity, Volume flow, Process gas temperature, Process gas pressure, NHV per gas constituent, NHV per gas type, Net heating value – combustion zone, Flare tip velocity, Maximum allowed flare tip velocity, CO2 emissions, CH4 emissions