Fluenta TFS Ultrasonic Transducers

Part of Fluenta's entry range of ultrasonic transducers, the TFS is the base level transducer designed for use in flaring applications around the globe.

Laboratory Levels of Precision in the Field

Measurement is the first step to control

Fluenta’s flare gas measurement systems offer dual ultrasound measurement modes to ensure high accuracy in challenging conditions, utilizing both Continuous Wave (CW) and Chirp signal processing for precise “time-of-flight” determination.

Continuous Wave (CW) Mode

In CW mode, the system sends a signal with constant frequency and amplitude. This is ideal for stable, predictable flow environments. CW mode provides a steady signal that tracks gas flow with high reliability, ensuring accurate measurements when gas flow velocity is within a predictable range.

Chirp Signal Processing Mode

The Chirp mode, on the other hand, employs time-varying signals that sweep through a range of frequencies. This signal processing technique is critical for handling complex, rapidly changing gas flows, where a single-frequency signal might be inadequate. By using Chirp signals, Fluenta’s system maintains accuracy even when the flow velocities fluctuate across a wide range. This method helps isolate the gas flow signal from background noise, allowing for more precise “time-of-flight” measurements.

Time-of-Flight Accuracy

Both CW and Chirp modes rely on the time-of-flight principle, which measures the time it takes for an ultrasonic pulse to travel from a transmitter to a receiver through the gas. This principle allows Fluenta to achieve an impressive ±1% accuracy, even in high-velocity or unstable gas flow conditions. The use of dual ultrasound modes means that the system can adapt to varying conditions, from slow and steady flows to high-velocity bursts, without losing precision.

Future-Proofing and Compliance

Fluenta’s ultrasonic transducers, including those equipped with TFS technology, provide a non-intrusive measurement method ideal for installations where regulations are becoming more stringent. While current regulations often require only 5% accuracy, Fluenta’s system, with its laboratory-level precision, ensures that operators are prepared for future regulatory tightening. This is important as controlling flaring more precisely is a key focus in reducing environmental impacts.

Fluenta’s dual-mode ultrasound measurement capability enables operators to maintain tight control over flare gas emissions, future-proofing their installations, and ensuring long-term compliance with evolving regulatory standards.

Applications

The Essential Role of Ultrasonic Flare Gas Measurement

In today’s oil, gas, and petrochemical industries, ultrasonic flare gas measurement plays a crucial role in both regulatory compliance and operational efficiency.

Onshore and Offshore Flare Gas Measurement

Fluenta’s flare gas measurement solutions are highly adaptable and suited for both onshore and offshore oil and gas operations due to their robust design, accuracy, and ability to function in extreme environments.

Features and Highlights

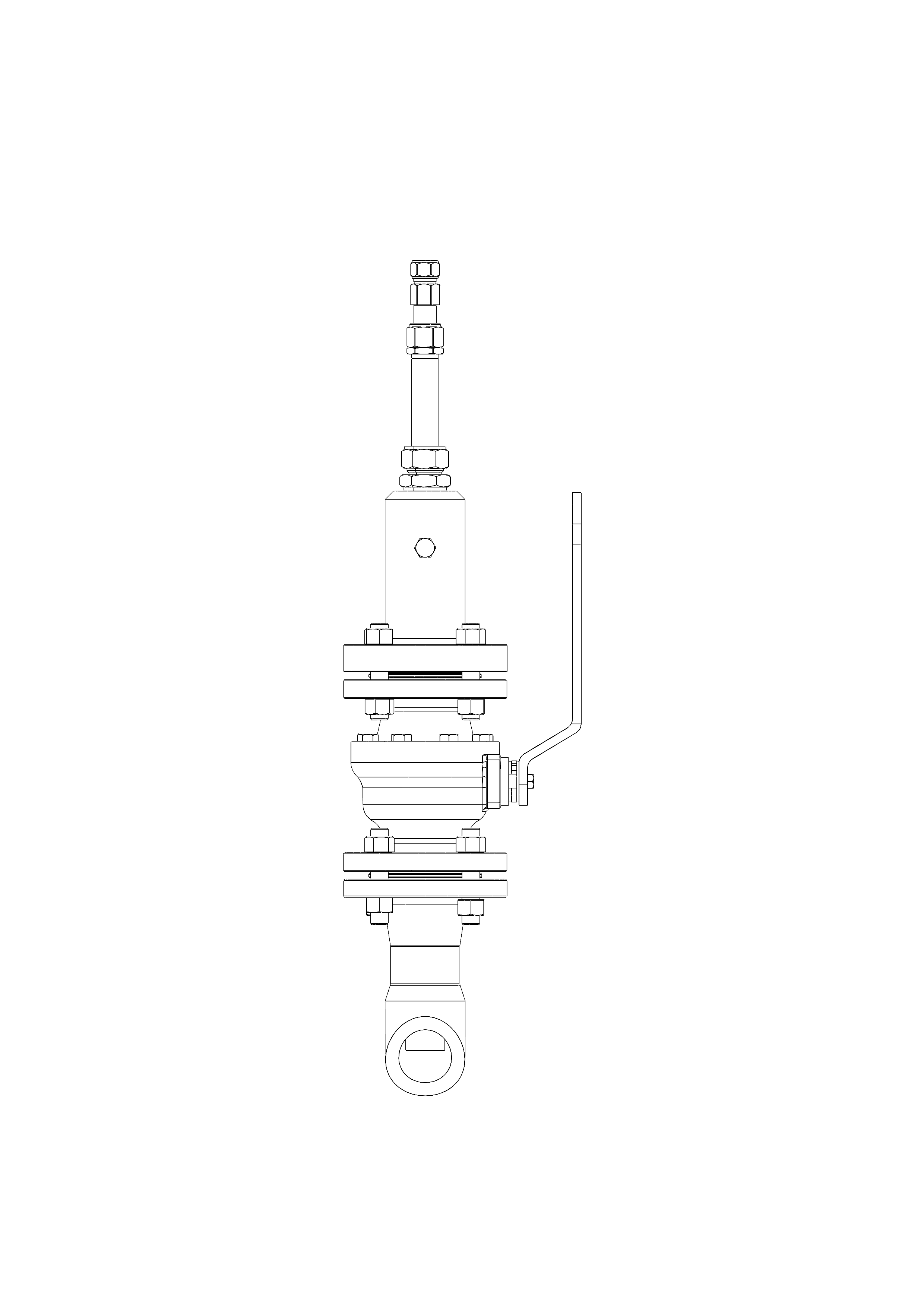

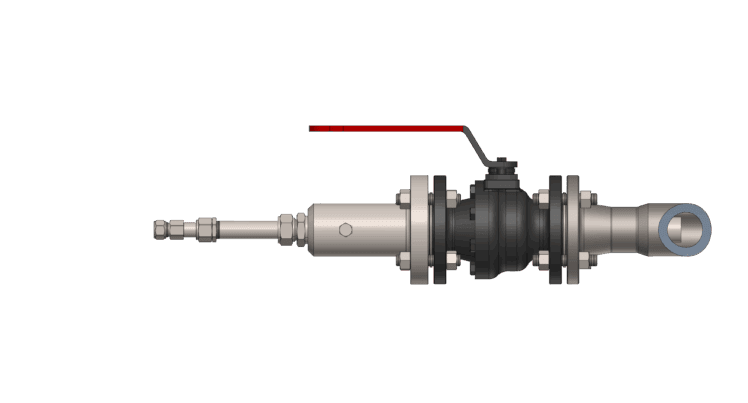

The TFS can be installed in either a single path or a dual path configuration. The dual path can be configured to either provide heightened security in terms of redundancy, when data continuity is of utmost importance or a more accurate measurement as with a dual path accuracy as high as ±0.1% can be achieved.

To achieve accurate readings, the TFS only requires 15 pipe diameters worth of straight piping (10 diameters upstream and 5 diameters downstream)

While the TFS transducer is constructed from SS316/Titanium as a standard, it may be available in other custom materials as well such as Incomel, Hastelloy, Duplex, 6Mo etc.

Key Specifications

Measurement Parameters

Standard and actual volume flow, mass flow, totalized standard volume flow, totalized mass flow, molecular weight, standard density, actual density, pressure, temperature, speed of sound, gas velocity

Certifications

ATEX: Presafe 17ATEX11794X

CSA: 18CA70182730 X – Class I Div 1

Inmetro: DNV 18.0077 X

Operating Temperature

-94 to +293 °F (-70 to +145 °C)

Operating Pressure

11.6 – 145 psiA (0.8 to 10 barA)

Flow Velocity Range

0.1 – 394 ft/s (0.03 – 120 m/s)

Accuracy

Standard: ± 2.5% to 5%

Optional: ± 1% to 2%

Repeatability

Better than 1% of volume flow for specific velocities

Turn Down Ratio

4000:1