Fluenta’s flare gas measurement solutions are highly adaptable and suited for both onshore and offshore oil and gas operations due to their robust design, accuracy, and ability to function in extreme environments. The oil and gas industry presents unique challenges in each setting, but Fluenta’s technology, such as its ultrasonic meters, addresses these challenges through innovation and advanced engineering.

1. Challenging Environments

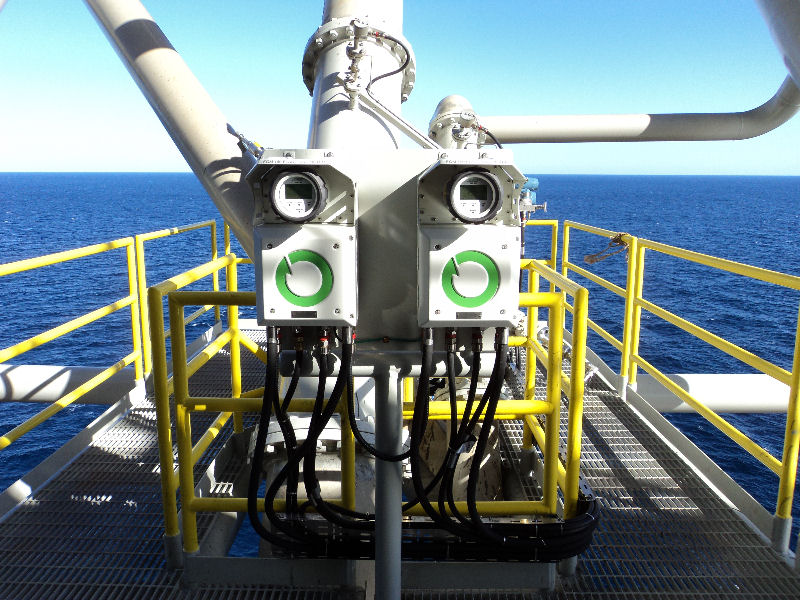

Offshore operations often face harsher environmental conditions, including high winds, saltwater corrosion, and extreme weather events. Onshore environments, while typically more stable, may also experience extreme temperatures and dust exposure. Fluenta’s flare gas measurement systems are designed to withstand such challenges through their durable construction, corrosion-resistant materials, and advanced electronics. This makes them ideal for deployment on offshore platforms, where durability and reliability are paramount for uninterrupted operations.

Offshore platforms often deal with fluctuating pressure, humidity, and temperature conditions due to their open-sea location. Fluenta’s ultrasonic technology is engineered to provide consistent accuracy, even in the face of such dynamic environmental factors. Similarly, in onshore facilities where there may be variable gas compositions and large-scale installations, Fluenta’s solutions can handle the demands of constant monitoring and complex operations.

2. Flexibility in Installation

The modular design of Fluenta’s flare gas meters allows for easy installation and integration into both offshore and onshore systems. Offshore platforms are typically constrained by limited space, requiring equipment that is compact yet capable of high-performance measurements. Fluenta’s systems are flexible and compact enough to be installed in the confined spaces found on offshore platforms while still delivering precise data in real time.

Onshore facilities, on the other hand, may have more space but often require integration with existing infrastructure, which can vary significantly in design. Fluenta’s solutions are versatile and can be easily incorporated into existing systems, providing accurate measurements without the need for extensive modifications or downtime during installation. The ability to customize the system for specific needs, whether offshore or onshore, ensures that operators can maintain compliance with environmental regulations without costly delays.

3. Wide Operational Range

One of the standout features of Fluenta’s technology is its ability to operate in a wide range of conditions. Offshore operations often involve high-pressure gas flows and varying gas compositions due to the extraction of hydrocarbons from deep beneath the ocean floor. Onshore facilities, while generally more stable, can also experience variations in gas composition due to the nature of refining or processing hydrocarbons.

Fluenta’s ultrasonic meters are designed to handle a wide spectrum of gas compositions and flow rates, ensuring accurate measurement whether offshore or onshore. Moreover, these systems are capable of performing in extreme temperatures, from cryogenic environments in gas liquefaction processes to high temperatures in refining applications. This versatility makes them suitable for both offshore and onshore flare stacks, regardless of the environmental conditions or gas characteristics.

4. Accurate Real-Time Data for Compliance

In both onshore and offshore environments, regulatory compliance is critical. Strict regulations are in place to minimize greenhouse gas emissions and ensure safety during oil and gas extraction and refining processes. Accurate real-time data on flare gas emissions is essential for meeting these regulatory requirements.

Fluenta’s systems provide continuous, real-time monitoring of flare gas emissions, enabling operators to adjust their operations on the fly to stay within emission limits. This is particularly important offshore, where access for maintenance or adjustments may be limited, and real-time data is essential for maintaining compliance. Similarly, onshore operations benefit from Fluenta’s systems by being able to track emissions continuously, ensuring that they remain within permitted thresholds and avoiding regulatory fines.

5. Cost Efficiency and Maintenance

Offshore platforms are often located far from land, making maintenance and repair operations difficult and expensive. Fluenta’s products are designed for durability and low maintenance, reducing the need for frequent servicing. Their robust construction and advanced diagnostics ensure long service life, even in the demanding conditions of offshore oil and gas platforms.

For onshore facilities, cost efficiency is also important, especially in large-scale operations. Fluenta’s flare gas meters are designed to provide accurate measurements with minimal intervention, allowing operators to focus on optimizing production processes rather than performing regular maintenance on the meters. This improves overall operational efficiency and helps reduce the cost of regulatory compliance.

6. Seamless Integration with Digital Systems

In both onshore and offshore environments, the trend toward digitalization and smart oil fields has increased the need for systems that integrate seamlessly with data analytics platforms. Fluenta’s flare gas measurement solutions are designed with this in mind, providing real-time data that can be fed into larger data management systems. This enables operators to track emissions, perform predictive maintenance, and optimize operations more effectively.

The ability to monitor flare gas in real-time and integrate this data with other operational systems is invaluable for both offshore and onshore operators looking to improve efficiency and comply with regulations.

Conclusion

Fluenta’s flare gas measurement solutions offer the accuracy, durability, and flexibility needed for both onshore and offshore oil and gas operations. Their ability to function in extreme environments, provide real-time data, and seamlessly integrate with existing infrastructure makes them an ideal choice for operators looking to improve efficiency and maintain compliance. Whether facing the harsh conditions of offshore platforms or the large-scale demands of onshore facilities, Fluenta’s products deliver the precise, reliable measurements needed to optimize flare gas management.