Upstream Oil and Gas Industry

Flare Gas Management in the Oil and Gas Industry

We are the preferred supplier of flare measurement to many multinational companies, and we have worked with a who’s who of the oil of gas industry, having over 4000 meters currently deployed in the industry globally.

The range of different gas compositions we can measure in is wide, as is the range of temperatures and other process conditions that can be faced. Whilst routine flaring has been vastly reduced, partly as a result of the increased accuracy of measurement, emergency flaring is very much an essential safety feature on Oil and Gas installations.

Emergency flaring can often reach incredible velocities. Other flare measurement technologies and even some ultrasonic applications that use probes in the gas flow are simply not able to cope. Fluenta sensors however, can cope with, and provide measurement in gas velocities up to 120 meters per second, with an industry-leading turndown ratio of 4000:1

Our full range of solutions is applicable to these installations. Whilst cost-effective solutions such as the standard TFS sensors are the best option where there’s a predictable gas mix and a limited range of process conditions, we also have some more specialist sensors able to provide consistent measurements in projects where extremes of temperature need to be within specification, and also when harder gas mixtures (such as higher CO2 or H2) are encountered.

Put simply – when you need it the most – we’re still here.

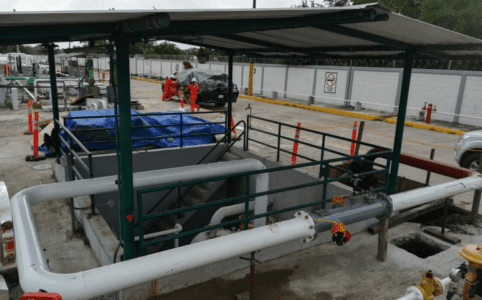

Case Studies – Lack of Space

Challenge Ultrasonic flow meters require a certain amount of straight piping free from any obstructions such as bends, valves etc. for them to measure the flow accurately. In this case the flare left the knockout drum and went immediately to the underground channel leaving not enough straight piping for a flare meter to be installed. […]

Case Study – Corrosive Gases

At Fluenta, we pride ourselves on our flexible approach to problem-solving, delivering innovative solutions that exceed client expectations, no matter how challenging the problem

Case Studies – Quick Turnaround

Indorama Venture’s olefins plant required the installation of two flare gas meters to meet their environmental reporting requirements.

Upstream Oil and Gas Industry