FlarePhase 350

Part of Fluenta's advanced range of ultrasonic transducers, the FlarePhase 350 is designed and optimized to measure flow in the most challenging of applications containing extreme temperature environments.

Handling the Heat - Flarephase 350

Ultrasonic flow measurement at extremely high temperatures

As with the other two offerings in the FlarePhase range, the FlarePhase 350 also features the novel “Active Phase Analysis Technology” and continuous measurement optimization making it a next generation ultrasonic transducer.

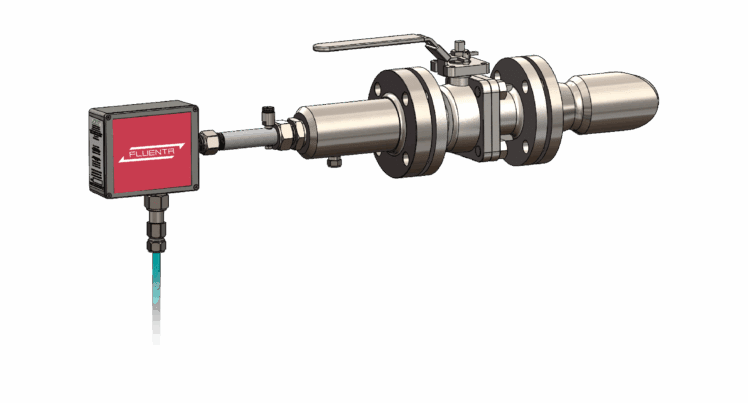

Flares may reach extremely high temperatures at which most ultrasonic sensors malfunction, thus making it impossible to take flow measurements. Fluenta’s solution to this problem is the FlarePhase 350. As part of the advanced FlarePhase range of ultrasonic transducers, the FlarePhase 350 also comes equipped with a new piezo-electric sensor made from advanced ceramics as well as extra heat shielding which ensures that it can continue measuring at extreme temperatures for extended periods of time while maintaining accuracy.

Packaged with the the FlareAmp and FlareAmp controller and also featuring the “Active Phase Analysis Technology” and continuous measurement optimisation, it boasts accuracies as high as ±0.75% making it a truly next generation ultrasonic measurement solution for extremely high temperature applications.

Applications

Extreme Temperature Environments

Fluenta’s FlarePhase 350 is designed to operate in extreme temperature environments, ranging from -40°C to +350°C. This broad temperature range makes it ideal for a variety of industrial applications where process conditions exceed 250°C, particularly in industries that rely on extreme thermal processes. Several key applications necessitate the use of FlarePhase 350 due to the […]

FlarePhase with High Levels of Carbon Dioxide

Fluenta’s FlarePhase technology is engineered to handle the demanding conditions of flare gas measurement in high carbon dioxide (CO2) environments

Features and Highlights

The “Active Phase Analysis Technology” combats the issue of phase shifts, which is an inherent issue faced by ultrasonic measurement devices and results in inaccuracies. By determining the phase shifts and calculating the necessary compensation, the FlarePhase range provides laboratory levels of accuracy in the field.

The FlarePhase 350 can be installed in either a single path or a dual path configuration. The dual path can be configured to either provide heightened security in terms of redundancy, when data continuity is of utmost importance or a more accurate measurement as with a dual path accuracy as high as ±0.75% can be achieved.

The FlarePhase 350 is capable of measuring gas flows at temperatures as high as +350°C (662°F) for extended periods of time.

Key Specifications

Measurement Parameters

Standard and actual volume flow, mass flow, totalized standard volume flow, totalized mass flow, molecular weight, standard density, actual density, pressure, temperature, speed of sound, gas velocity

Certifications

ATEX: ExVeritas 20ATEX0699 X

IECEx: EVX 20.0044X

Operating Temperature

-40 to 662 °F (-40 to 350 °C)

Operating Pressure

11.6 – 145 psiA (0.8 to 10 barA)

Flow Velocity Range

0.1 – 394 ft/s (0.03 – 120 m/s)

Accuracy

Standard: ± 2.5% to 5%

Optional: ± 0.75% to 2%

Repeatability

Better than 1% of volume flow for specific velocities

Turn Down Ratio

4000:1