Support Solutions

Fluenta Americas Establishes New Sales and Support Hub in Houston’s Energy Corridor

New Fluenta Offices, Houston, USA

Fluenta talks Methane in World Pipelines Magazine

Methane Monitoring Fluenta’s Chief Scientist, Dr Neil Bird, recently featured in the May 2025 edition of World Pipelines, outlining the growing urgency of methane emissions management and introducing Fluenta’s latest innovation, FlareSens. In the article, Dr Bird emphasizes methane’s significant impact on climate change, noting, “Methane accounts for nearly a quarter of global warming observed […]

FGM 160 Flare Gas Meter: Accurate Out of the Box, Validated by CEESI

Why This Test Was Important Kuwait Oil Company (KOC) has a strong track record in reducing gas flaring, cutting it down from 17% in 2005 to 0.45% in 2022/23. It is a public signatory of the World Bank’s Zero Routine Flaring by 2030 initiative. As part of Fluenta’s engagement with KOC, the FGM 160 Flare […]

Solving CO₂ Challenges in Flare Gas Measurement

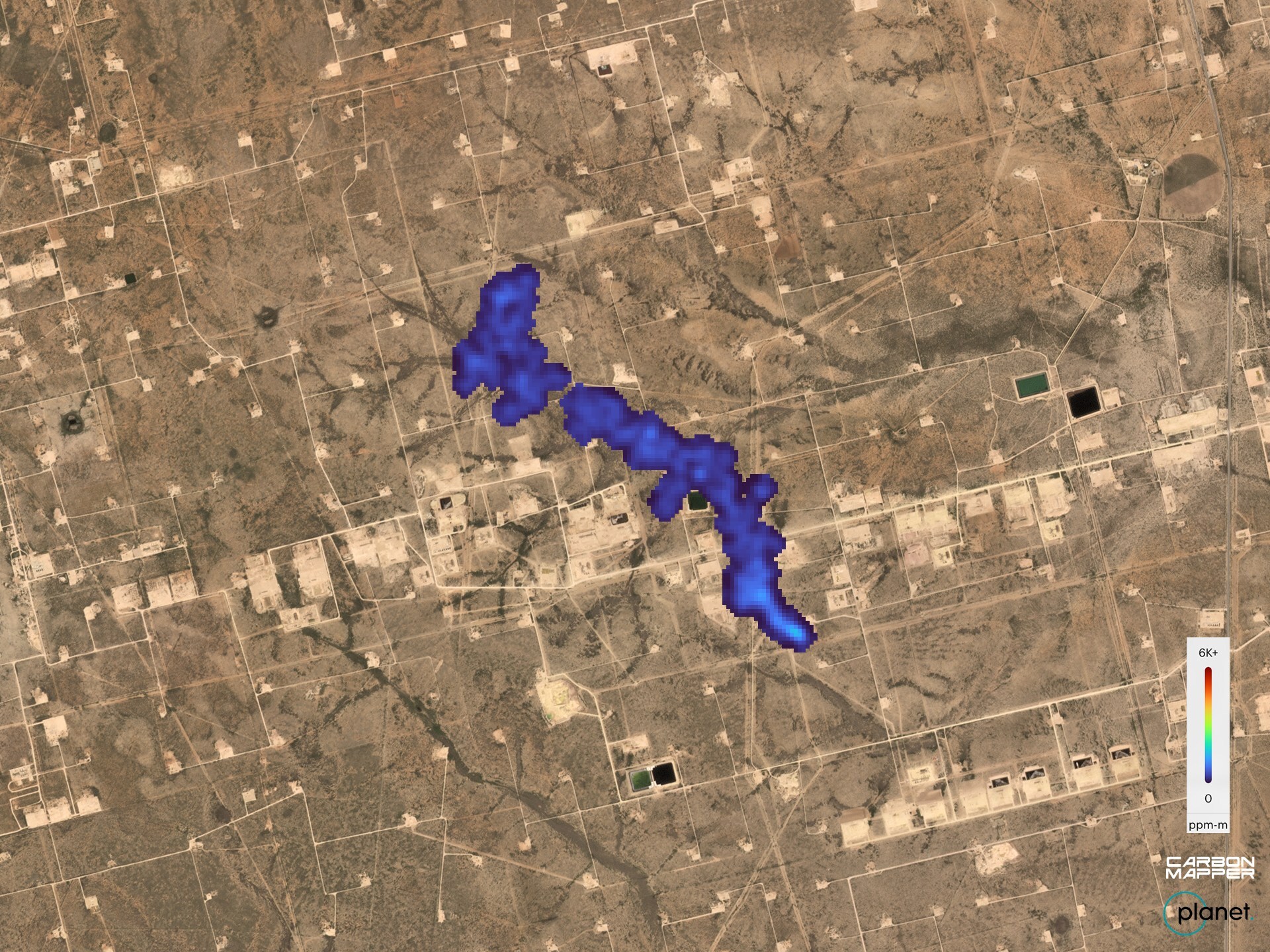

MethaneSat, a project spearheaded by the Environmental Defence Fund, is revolutionising monitoring of flare gas and general methane leakage by providing high-resolution satellite data. By capturing accurate and frequent data, MethaneSat can identify and quantify point emissions sources, or combine measurements in a locality, or even a whole region, enabling anyone oversight and hitherto unprecedented […]

Achieve Precise Flare Gas Measurement – Download Your Free Article

Flare gas systems encounter uniquely harsh and dynamic conditions that push flow measurement instruments to their limits

Methane Measurement for OGMP 2.0

A recent study by MethaneSAT (read here) confirms what the industry has long suspected—smaller, dispersed methane sources account for the majority of emissions in the U.S. oil and gas sector. The study highlights a fundamental flaw in methane reduction strategies: while satellite data provides a big-picture view, it lacks the real-time accuracy needed to control […]

Supporting Algeria’s Redefined Environmental and Economic Standards through Flare Gas Measurement

Algeria is cutting gas flaring with advanced measurement tech, reducing emissions, and boosting energy efficiency for a sustainable future.

FlareSpec – Meeting Demands and Moving Forward

Fluenta has recently developed a powerful and accurate tool to predict the performance of it’s range of flare-gas measurement solutions in any provided process conditions. The new tool is a game-changer for operators looking for confidence, or who have been previously bitten with flare-measurement systems unable to cope with their actual processes. Published this week […]

The Impact of the European Methane Regulation on Flaring in the Oil and Gas Industry

EU Methane Regulation in the Oil and Gas Industry

The Impact of the Inflation Reduction Act on Reducing Methane Emissions in the U.S. Oil and Gas Industry

The Impact of the Inflation Reduction Act on Flaring in the U.S. Oil and Gas Industry The Inflation Reduction Act (IRA), signed into law in August 2022, includes various measures aimed at addressing climate change, with a focus on reducing methane emissions, particularly from flaring in the oil and gas sector. One of the act’s […]