Why This Test Was Important

Kuwait Oil Company (KOC) has a strong track record in reducing gas flaring, cutting it down from 17% in 2005 to 0.45% in 2022/23. It is a public signatory of the World Bank’s Zero Routine Flaring by 2030 initiative.

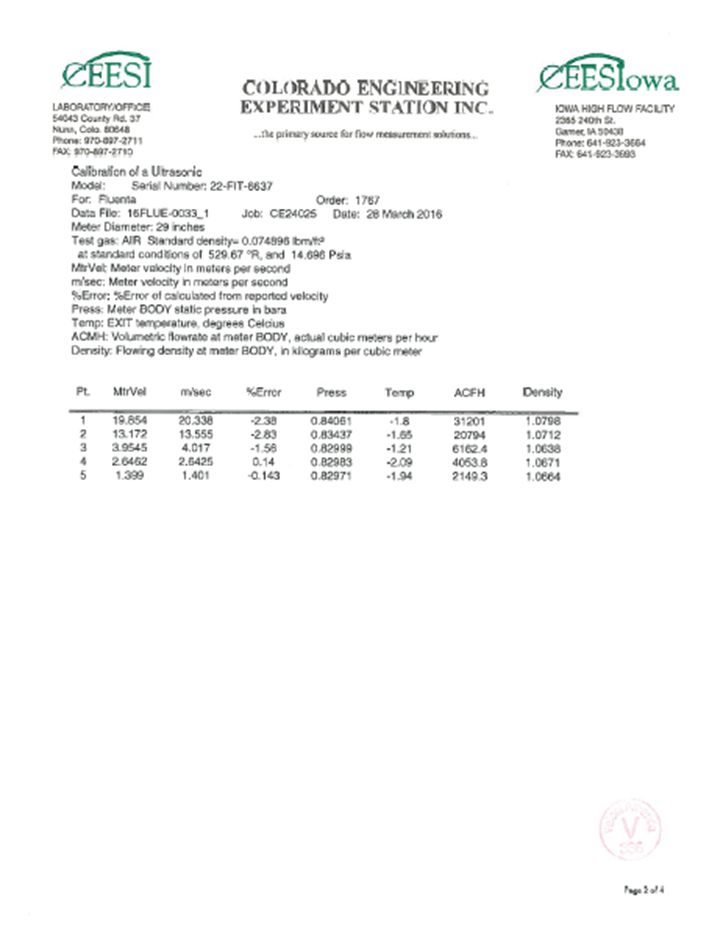

As part of Fluenta’s engagement with KOC, the FGM 160 Flare Gas Meter was tested at the CEESI facility in Colorado. While not a customer requirement, Fluenta aimed to demonstrate that the FGM 160 delivers high-accuracy results without calibration, even under difficult flare gas conditions—low velocity, wide pipe diameter, and unstable flow. This is particularly relevant in flare gas measurement, where accurate data is critical for emissions compliance and safety, and where many meters require tuning or recalibration on site.

Test Setup and Methodology

Fluenta chose CEESI (Colorado Engineering Experiment Station, Inc.) thanks to its NIST-traceable certification and its ability to simulate low-flow, large-diameter flare gas scenarios.

| Parameter | Details |

| Test Facility | CEESI, Colorado |

| Pipe Diameter | 30” spool piece |

| Flow Velocity Range | 1 – 20 m/s |

| Calibration Performed | None (meter test out-of-the-box) |

| Data Collection Duration | 30 seconds per run to ensure stable conditions |

| Meter Comparison | Fluenta FGM 160 vs. CEESI reference meter |

Both the Fluenta and reference meters were connected to CEESI’s central data acquisition system. Readings were taken over 30-second intervals to simulate stable, real-world flow and calculate average error margins.

Results

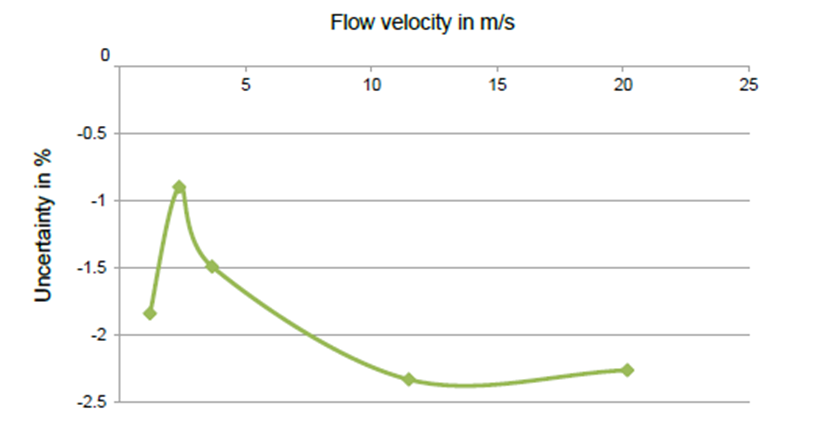

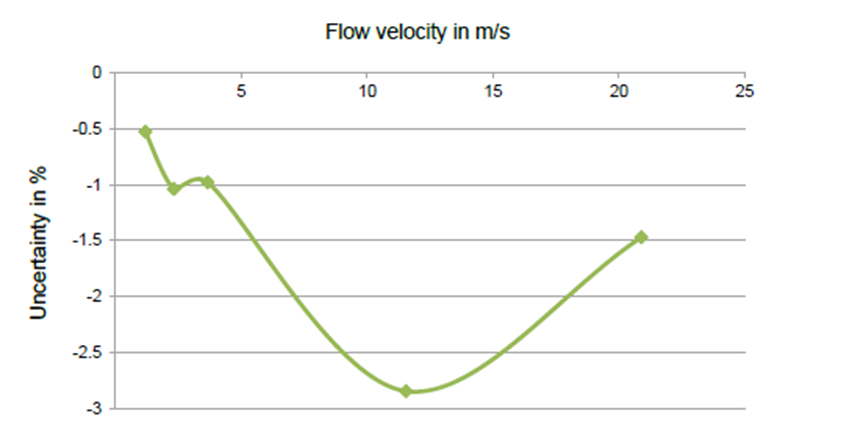

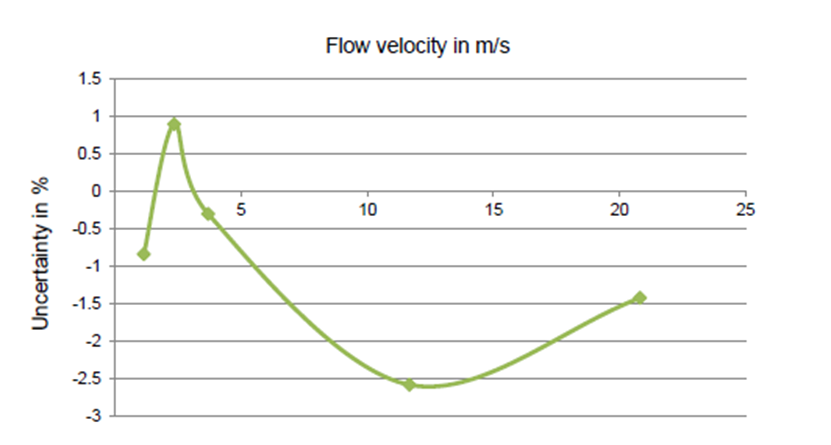

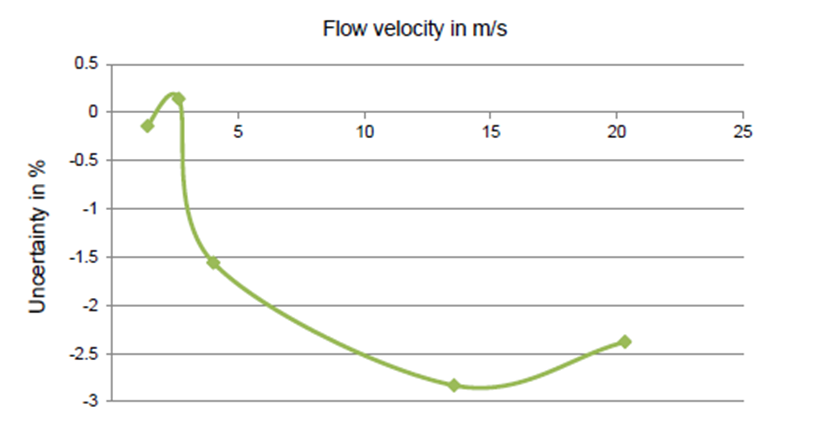

- The Fluenta FGM 160 performed with an uncertainty below 3%, without any calibration.

- This performance held across the full range of low velocities (1–20 m/s).

- Multiple consistent results were achieved in a single test session, an uncommon outcome at third-party facilities, especially for low flow flare gas.

“Flare gas is unpredictable by nature…composition shifts, flow rates fluctuate, and events can last only a few seconds. The FGM 160 uses a time-of-flight ultrasonic measurement principle, which is inherently well-suited to these conditions. What this test proves is that our meter delivers stable, highly accurate measurement without any calibration, even at low velocities on a 30” line. That’s not something thermal mass or other technologies can reliably achieve without complex setup or real-time recalibration.”

Why This Matters

Flare gas systems are uniquely difficult to measure due to several factors:

- Variable composition: the gas mix can change rapidly. Methane, CO₂, H₂S, and heavier hydrocarbons all behave differently.

- Low, erratic flow: flow rates often drop below 5 m/s or spike briefly during venting events.

- Short-duration events: some flaring events last just seconds, making real-time accuracy critical.

- Difficult site conditions: installations often lack optimal straight pipe runs or access for calibration.

Many technologies, especially thermal mass meters, rely on external inputs (like temperature and pressure) to infer flow. They often require frequent recalibrations or data smoothing to compensate for shifting conditions, but by the time they stabilise, the flare event may have passed.

By contrast, the FGM 160 uses time-of-flight ultrasonic technology, which directly measures the transit time of gas pulses across the pipe. This makes it highly responsive and less dependent on assumed gas properties or static inputs.

Graphical Results: Sub-3% Uncertainty Achieved Across Flow Velocities Without Calibration

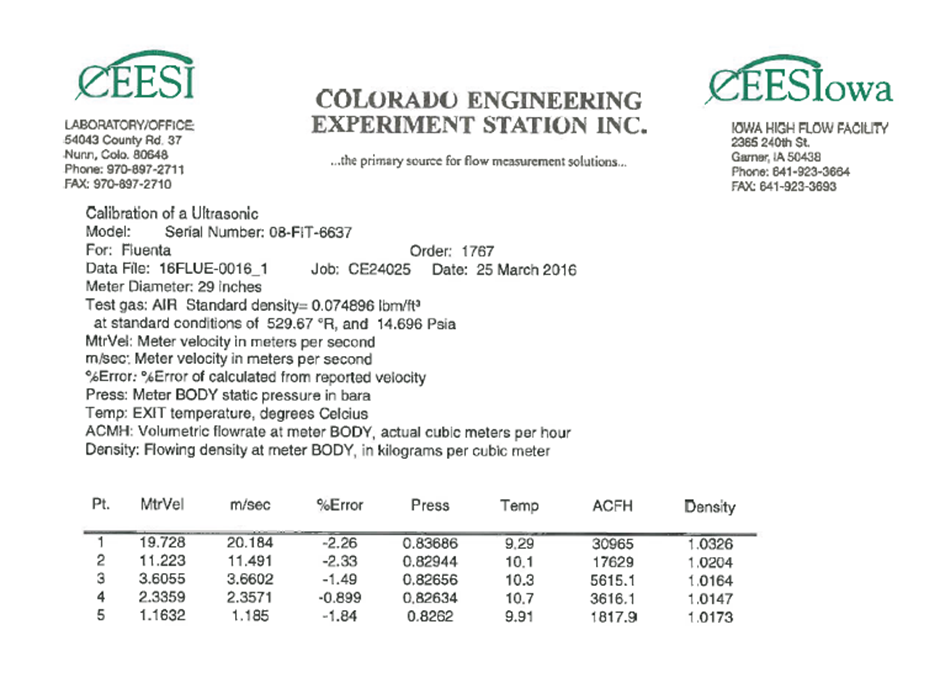

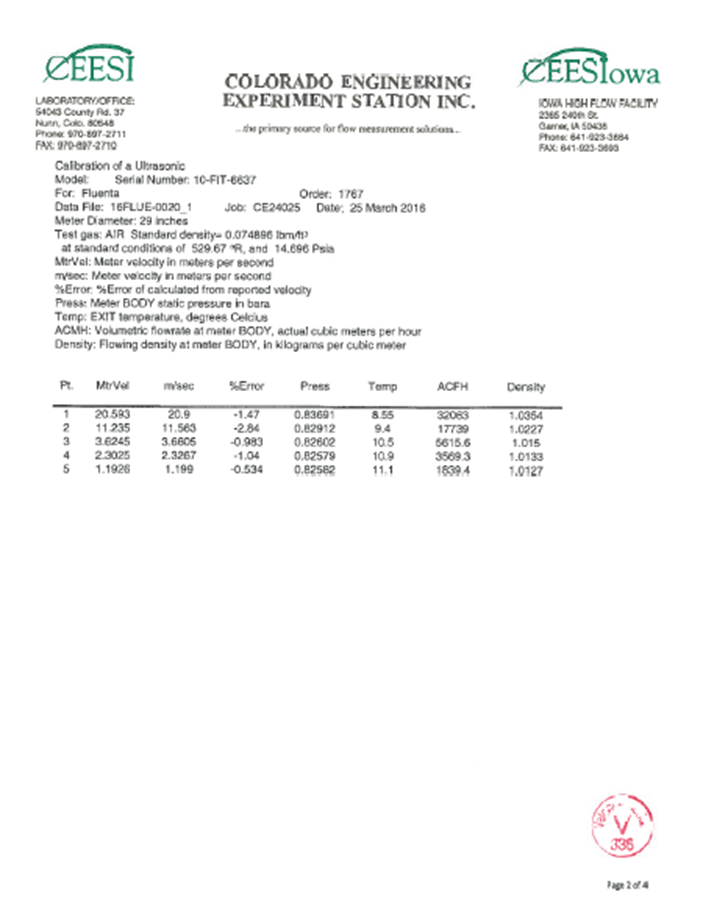

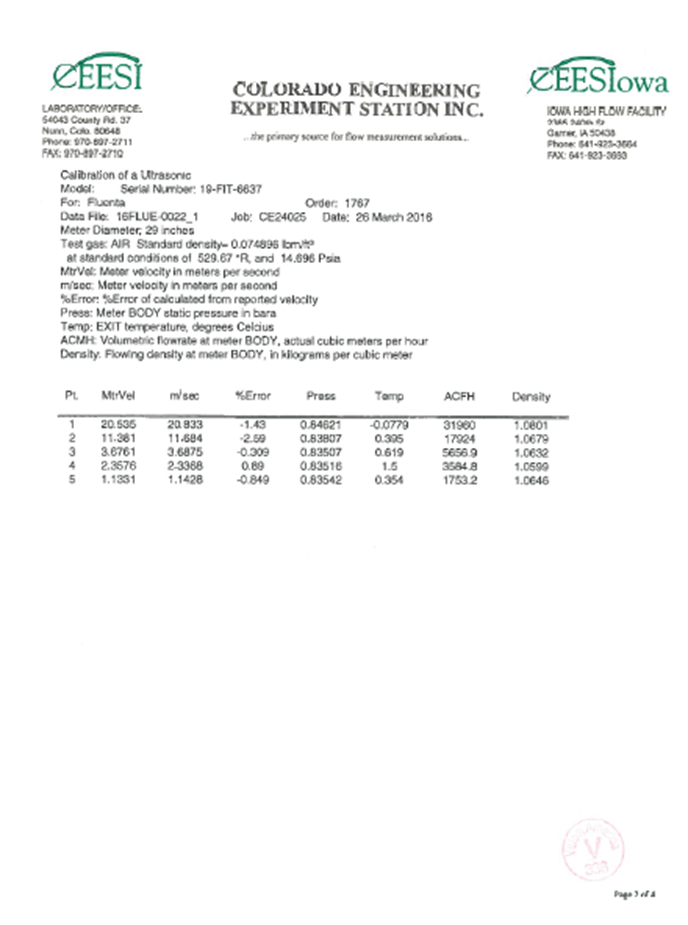

Third-Party Validation: CEESI Certification

Next Steps

If you’re planning a flare gas measurement installation, particularly where calibration access is limited, this test confirms that the FGM 160 can deliver high accuracy straight out of the box and reliably under difficult conditions—such as low flow, large-diameter pipes, and fluctuating gas composition—making it a strong fit for both new and retrofit installations.