A NEW APPROACH TO HIGH CO2 MEASUREMENT

Reliable, real-time ultrasonic measurement for up to 100% CO₂ concentrations

The challenge of measuring high concentrations of CO₂ in flare gas has long posed risks and regulatory hurdles for the oil and gas industry. Fluenta’s FlarePhase technology brings a breakthrough solution, enabling precise and reliable measurement even in the most CO₂-rich environments. Discover how our technology is transforming high-CO₂ measurement, backed by rigorous testing and proven industry success.

Download Testing WhitePaperThe High CO₂ Measurement Challenge

Flare gas in industrial settings, particularly in CCUS (Carbon Capture, Utilisation, and Storage) or EOR (Enhanced Oil Recovery), can often contain significant CO₂ concentrations.

High levels of CO₂ (anything over 30%) poses a unique challenge in ultrasonic flare gas measurement because CO₂ acts as a powerful absorber of ultrasonic signals, reducing their strength and compromising measurement accuracy. Traditional measurement methods struggle in high-CO₂ environments, often leading to:

- Non-compliance with regulatory standards,

- Safety risks due to unreliable data, and

- Operational inefficiencies stemming from inconsistent measurements.

With increasing regulatory demands on emissions monitoring, accurate CO₂ measurement is now an essential requirement, not an optional feature.

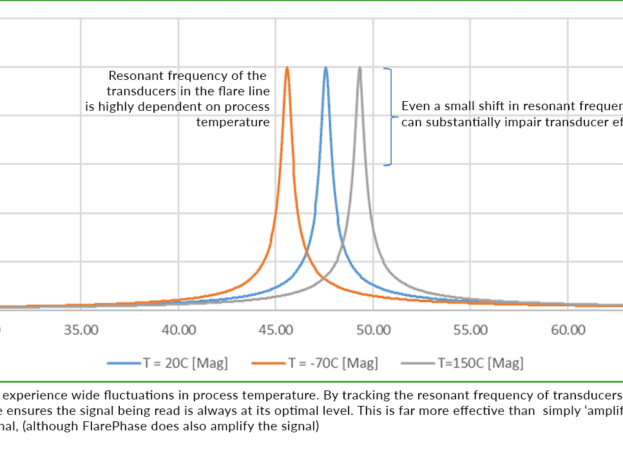

Adding to the challenge, CO₂’s signal absorption effect becomes even more pronounced under the fluctuating temperatures common in flare systems.

High temperatures cause a phenomenon known as Resonant Frequency Drift, where even minor temperature changes can reduce measurement efficiency. For example, a shift as small as 1 kHz (equivalent to circa 40°C which are extremely common in flare lines) can reduce the efficiency of standard transducers by around 40% leading to a substantial decrease in data accuracy.

Fluenta’s FlarePhase technology is specifically engineered to counter these effects, maintaining precision even at extreme CO₂ concentrations and across wide temperature ranges.

By adapting to both CO₂’s signal-absorbing properties and thermal fluctuations, FlarePhase offers a robust, reliable solution that ensures compliance, safety, and operational efficiency where other systems fall short.

Introducing FlarePhase: Reliable Measurement for High CO₂ Environments

Fluenta’s FlarePhase transducers are purpose-built to handle the extreme conditions of high-CO₂ flare gas systems. Key features include:

- Extended Temperature Range: FlarePhase withstands significant thermal shifts, thanks to proprietary enhanced signal processing, maintaining accuracy across extreme temperature variations.

- Frequency Stability: FlarePhase addresses resonant frequency drift, ensuring optimal signal reception and accuracy even amid frequent temperature changes.

- High CO₂ Compatibility: FlarePhase provides precise measurements at CO₂ concentrations up to 100%, overcoming the typical signal attenuation that degrades accuracy in standard systems.

- Adaptability Across Flow Rates: tested from low to high flow rates, FlarePhase consistently delivers stable data, ensuring reliability across varying flare system conditions.

With FlarePhase, operators gain reliable, real-time data that supports regulatory compliance, safety, and operational efficiency, even in the most demanding high-CO₂ environments.

Third Party Testing Results

Fluenta’s FlarePhase technology has undergone rigorous testing with the Instituto de Pesquisas Tecnológicas (IPT) to prove its capability in high-CO₂ environments from 0% to 100%. Key results include:

- CO₂ Concentration Testing: successful measurements at CO₂ levels of up to 99.1%.

- Accuracy and Repeatability: high precision demonstrated across varying flow rates and pipe sizes, even under challenging conditions.

- Industry Standards: exceeds industry requirements, ensuring reliable performance for compliance and safety.

For a full breakdown of testing methods, data, and outcomes, download our testing whitepaper.

Download Testing WhitePaperApplications for High-CO₂ Measurement Solutions

FlarePhase technology is ideal for settings where high CO₂ concentrations are typical, such as:

- CCUS: monitoring of CO₂ levels, ensuring safety and compliance in CO₂-heavy injection and storage processes.

- EOR: provision of accurate emissions data during CO₂ injection used to boost oil recovery, critical for operational efficiency and regulatory adherence.

- Petrochemical Production: supporting high-accuracy measurement in processes like ethylene oxide production, methanol synthesis, and urea manufacturing, where high CO₂ emissions are prevalent.

- Natural Gas Processing: ensuring compliance and safe emissions monitoring in CO₂-rich flare systems often found in gas sweetening and dehydration processes.

Our customers are already benefiting from FlarePhase’s capabilities to improve safety and optimise operations. Speak with us today for more information.

Get in touch