Downloads and Resources

Download our new Brochure

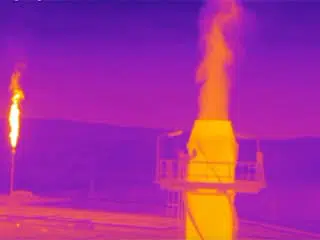

Fluenta’s mission is to deliver superior data solutions to our valued customers, with a primary focus on enhancing flare gas measurement within the energy sector.

As we evolve, we’re extending our expertise to serve a broader range of industrial applications.

Better data leads to better decisions in the journey to decarbonization but also enables precise record-keeping and ensures unwavering regulatory compliance.

At Fluenta, we proudly lead the way in ultrasonic flare gas measurement, setting the industry standard with our exceptional expertise. Our relentless pursuit of innovation has resulted in groundbreaking advancements, including harnessing technology and materials to measure at extreme temperatures,

and advanced Digital Signal Processing techniques for measurement of difficult gases. These innovations enable us to achieve unparalleled levels of precision and consistency in measurements, even when confronted with complex gas mixtures that have traditionally posed challenges.

As we continue to explore new applications, materials, and technologies, our primary objective is to harness this newfound knowledge to create shared value. We are committed to delivering benefits to our valued customers and industry regulators, aligning with the broader environmental goals that the energy sector is actively pursuing.

DownloadFGM 160 Flow Computer

DownloadsFlarePhase 250

DownloadsFlarePhase 350

DownloadsFlarePhase Cryo for LNG and extreme low temperature applications

DownloadsFlareSens emissions monitoring

DownloadsFluenta TFS Ultrasonic Transducers

DownloadsFluenta TFS-55

DownloadsServicing

DownloadsSupport

DownloadsSupport Solutions

DownloadsUFM Manager – Fluenta software

DownloadsMethane Measurement for OGMP 2.0

A recent study by MethaneSAT (read here) confirms what the industry has long suspected—smaller, dispersed methane sources account for the majority of emissions in the U.S. oil and gas sector. The study highlights a fundamental flaw in methane reduction strategies: while satellite data provides a big-picture view, it lacks the real-time accuracy needed to control […]

LNG and Cryogenic Gas Flows

Fluenta’s FlarePhase Cryo technology is specifically designed to operate in extreme low-temperature environments, ranging from -200°C to +250°C

Continue readingExtreme Temperature Environments

Fluenta’s FlarePhase 350 is designed to operate in extreme temperature environments, ranging from -40°C to +350°C. This broad temperature range makes it ideal for a variety of industrial applications where process conditions exceed 250°C, particularly in industries that rely on extreme thermal processes. Several key applications necessitate the use of FlarePhase 350 due to the […]

Continue readingFGM 160 Flare Gas Meter: Accurate Out of the Box, Validated by CEESI

Why This Test Was Important Kuwait Oil Company (KOC) has a strong track record in reducing gas flaring, cutting it down from 17% in 2005 to 0.45% in 2022/23. It is a public signatory of the World Bank’s Zero Routine Flaring by 2030 initiative. As part of Fluenta’s engagement with KOC, the FGM 160 Flare […]

Petronas Upgrades to Fluenta

In 2020, Malaysia’s government-owned oil and gas company, Petronas started installing Fluenta flare gas meters

Continue readingCase Studies – Weathering the Cold

Some clients are located in extremely cold regions or have cryogenic process conditions which make accurate measurement very difficult as both of these put significant stress on the meters.

Continue readingNOG (Nigerian Oil and Gas) Energy Week

The NOG Energy Week 2025, held in Abuja, Nigeria, is one of the key events for the Nigerian energy sector.

PetroAfrica 2024

PetroAfrica is a premier conference and exhibition for the oil and gas industry in Africa.

Continue readingFluenta talks Methane in World Pipelines Magazine

Methane Monitoring Fluenta’s Chief Scientist, Dr Neil Bird, recently featured in the May 2025 edition of World Pipelines, outlining the growing urgency of methane emissions management and introducing Fluenta’s latest innovation, FlareSens. In the article, Dr Bird emphasizes methane’s significant impact on climate change, noting, “Methane accounts for nearly a quarter of global warming observed […]

Solving CO₂ Challenges in Flare Gas Measurement

MethaneSat, a project spearheaded by the Environmental Defence Fund, is revolutionising monitoring of flare gas and general methane leakage by providing high-resolution satellite data. By capturing accurate and frequent data, MethaneSat can identify and quantify point emissions sources, or combine measurements in a locality, or even a whole region, enabling anyone oversight and hitherto unprecedented […]

Continue readingAchieve Precise Flare Gas Measurement – Download Your Free Article

Flare gas systems encounter uniquely harsh and dynamic conditions that push flow measurement instruments to their limits

Continue readingFluenta talks Methane in World Pipelines Magazine

Methane Monitoring Fluenta’s Chief Scientist, Dr Neil Bird, recently featured in the May 2025 edition of World Pipelines, outlining the growing urgency of methane emissions management and introducing Fluenta’s latest innovation, FlareSens. In the article, Dr Bird emphasizes methane’s significant impact on climate change, noting, “Methane accounts for nearly a quarter of global warming observed […]

A Partnership Between Fluenta and SEGITEC Supports North African Nations’ Carbon Reduction Ambitions

May 27, 2024 — Cambridge, UK – Fluenta, a global leader in developing ultrasonic sensing technology to measure flare gas, has recently partnered with SEGITEC, an integrator of control and instrumentation solutions with strong roots in North Africa, to become its exclusive channel partner. Fluenta’s ultrasonic flare gas measurement solutions and SEGITEC’s established distribution network […]

Continue readingFluenta empowers Africa’s largest oil refinery with cutting-edge flare gas measurement technology

Fluenta empowers Africa’s largest oil refinery, Dangote, with cutting-edge flare gas measurement technology

Continue readingAchieve Precise Flare Gas Measurement – Download Your Free Article

Flare gas systems encounter uniquely harsh and dynamic conditions that push flow measurement instruments to their limits

FlareSpec – Meeting Demands and Moving Forward

Fluenta has recently developed a powerful and accurate tool to predict the performance of it’s range of flare-gas measurement solutions in any provided process conditions. The new tool is a game-changer for operators looking for confidence, or who have been previously bitten with flare-measurement systems unable to cope with their actual processes. Published this week […]

Technology Comparison: Thermal Mass Vs. Ultrasonic Meters for Flare Gas Measurement

This article describes and compares ultrasonic and thermal mass technologies used for flare gas measurement and highlights the advantages and disadvantages of each. For ultrasonic measurement, this article refers to Fluenta’s FGM 160 flare gas meter. Measurement Methods An ultrasonic flow meter sends ultrasonic signals across a pipe at a 45° angle to the direction […]

Continue reading21 Key Considerations to Make Before Choosing a Flare Gas Meter – A Checklist

Specifying a flare gas meter requires a thorough process to identify an installation’s needs and requirements.

Continue reading